Mastering Metallics

With the holidays right around the corner, we know the wheels in your mind are starting to turn (because we know ours are!). Wouldn’t you love to add some pizazz to those holiday sew-outs? Not only are we getting ready for the trick-or-treaters and turkey basters, but December is going to be here sooner than we think, so why not get these ideas ready and stay one step ahead of the game?

Christmas, Hanukkah, and Kwanzaa…what a way to end our year! All these end-of-the-year holidays bring us so much joy. Celebrations with family and friends wouldn’t be complete without your personal flare of some shimmering allure.

In this article, we are going to share our favorite tips for embroidering with metallic thread. Metallic thread can be tricky, and tricky can quickly turn to frustration. Hopefully, the tips in this article will help ease that frustration and help you produce some clean, beautiful, and memorable embroidery pieces.

Let’s begin with the structure of metallic thread. Metallic threads are no longer made from true metals, like in years past. They are now made from synthetic materials that can cause more problems while sewing than our other fibrous thread choices, such as cotton, rayon, and polyester. The delicate nature of metallic thread can cause numerous thread breaks and time-consuming twisting that can eventually affect the outcome of your design. Since these threads are made of synthetic materials, they are more prone to thread breaks due to their lack of elasticity versus some other thread types.

The most common issue we see in working with metallic thread is thread breakage. Because of its fragile nature, metallic thread tends to break more during sew-outs which causes interruptions in your sewing. To avoid the frustration of multiple thread breaks, we have some tips to help you run a smooth and clean metallic design.

When using metallic thread, always make sure to run your machine at a maximum speed of 600 stitches per minute. Although we tend to want machine speeds to be higher to minimize production time, the problems that may arise with these accelerated speeds may not be worth it in the long run. Slowing your machine down will reduce friction with your thread and help prevent unnecessary thread breakage.

Another key factor in minimizing thread breakage while using metallic thread is to ensure that you are using the proper needle. Using a larger needle will create a larger hole in your fabric which puts less stress on the metallic thread, reducing breakage. A quick tip that has helped many embroiderers is using a lubricant on your thread, such as silicon spray or thread conditioner, to make your metallic thread smoother and less prone to twisting while passing through the needle.

One of the most forgotten factors in minimizing breakage is your tension settings. As mentioned, metallic thread is fragile, and to help with breakage, we recommend completing tension tests on scrap fabric to test the tension on your machine. Thread tension is crucial when using metallic thread. While tight tension can cause multiple thread breaks, loose tension can cause your stitches to look unkept and sloppy. Finding that perfect balance is something that takes time but can be mastered with practice and learning your machine.

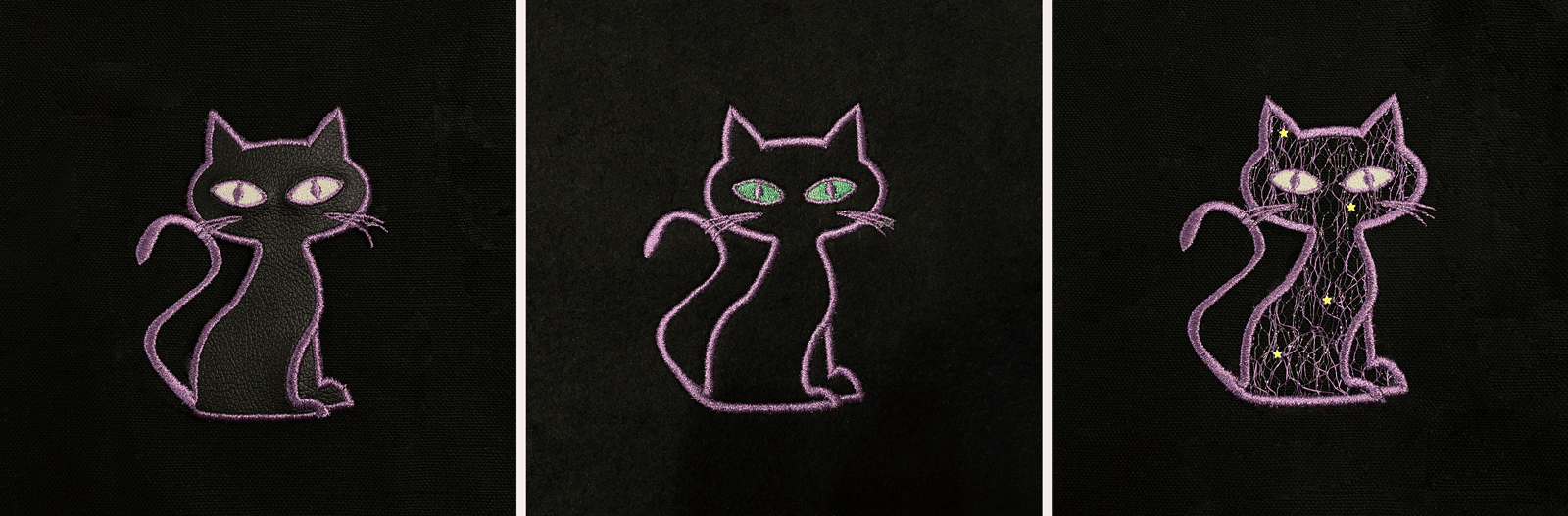

*Cat design shown in different applications using metallic thread (leather, felt and lace)

The delicacy of using metallic threads is something to master, so if you are in the same boat as many of us are, use these tips to help achieve that sparkle you are looking for. Take a moment to view and download our new FREE holiday designs, add that special personal touch to your holiday celebrations and visit our embroidery pricing page. Happy Sparkle-Stitching!

QUICK TIPS:

- Slow the speed on your machine for optimal design quality

- Use the proper needle when using metallic thread

- Check the tensions on your machine to relieve stress on your metallic thread

- Use high quality metallic threads; low quality threads tend to break and fray more frequently

- Use thread lubricant while using metallic threads to minimize thread breakage

- Use a horizontal stand for your thread spool to minimize thread twisting

- Use a spool net over your thread when using a vertical stand to reduce twisting and tangling

- Avoid highly complex designs when using metallic thread

(Left to right: Thread lubricant, Gunold metallic thread, thread net spool cover)