Single-Needle or Multi-Needle? Picking the Best Machine for Your Embroidery Goals

Embroidery is a creative and rewarding business venture that allows you to transform everyday items into personalized treasures. One of the first decisions you’ll face when starting your embroidery business is choosing between a single-needle or multi-needle embroidery machine. Both have their advantages and are suited for different business needs. In this guide, we’ll explore the key differences to help you decide which machine is right for your embroidery journey.

What is a Single-Needle Embroidery Machine?

A single-needle embroidery machine resembles a standard sewing machine. It has one needle and requires manual thread changes for each color in your design.

Advantages:

- Affordable Entry Point

Single-needle embroidery machines are significantly more budget-friendly, with prices typically ranging from $300 to $1,500. This makes them a practical option for those just starting in embroidery or exploring it as a hobby. The lower upfront cost reduces financial risk, especially for those unsure of how quickly they’ll grow their business. - Compact and Portable

Single-needle machines are small and lightweight, making them easy to move and store. They are ideal for home-based businesses with limited workspace or for those who want the flexibility to transport the machine to events, craft fairs, or classes. - Easy to Learn and Operate

With straightforward controls and user-friendly interfaces, single-needle machines are great for beginners. Many models include step-by-step tutorials, built-in design libraries, and intuitive touchscreens that make it simple to get started. This ease of use allows new embroiderers to focus on creativity rather than troubleshooting complex settings. - Versatility for Small Projects

Single-needle machines are perfect for smaller embroidery projects like monograms, patches, and logos. They work well on a variety of fabrics, allowing you to customize items such as towels, t-shirts, baby clothes, and bags. This versatility lets you cater to niche markets or create unique, personalized gifts. - Minimal Maintenance Requirements

With fewer moving parts compared to multi-needle machines, single-needle machines are easier to maintain. Regular cleaning and occasional oiling are often enough to keep them running smoothly, saving you time and money on servicing. - Low Noise Level

Single-needle machines operate quietly compared to multi-needle models, making them ideal for home use or shared spaces. You can work on your embroidery projects without worrying about disturbing family members or neighbors.

Disadvantages:

- Manual Thread Changes: With single-needle machines, you’ll need to change the thread manually for every new color or step in your design. This can be time-consuming, especially for intricate, multi-colored designs. To streamline the process, it’s crucial to use digitized files specifically optimized for single-needle machines. These files should minimize thread color changes by grouping colors together whenever possible.

- Design Size Limitations: The size of your embroidery designs can be limited by the hoop size your machine supports. Many entry-level single-needle machines, such as the Brother PE535 or Singer EM200, come with hoops that only support designs up to 4×4 inches. While this is sufficient for small projects like monograms or patches, it can restrict your creative potential for larger designs. If you want to work with bigger designs, consider investing in a machine like the Bernette Deco 70 or Janome Memory Craft 500E, which offer support for multiple hoop sizes, including larger options like 5×7 or 6×10 inches.

- Slower Production: The manual process and single-thread capability can slow down output.

What is a Multi-Needle Embroidery Machine?

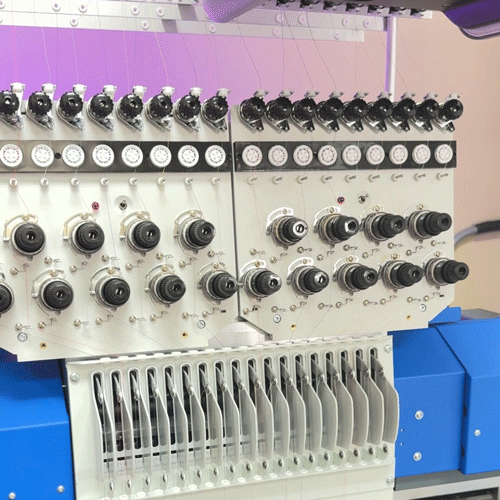

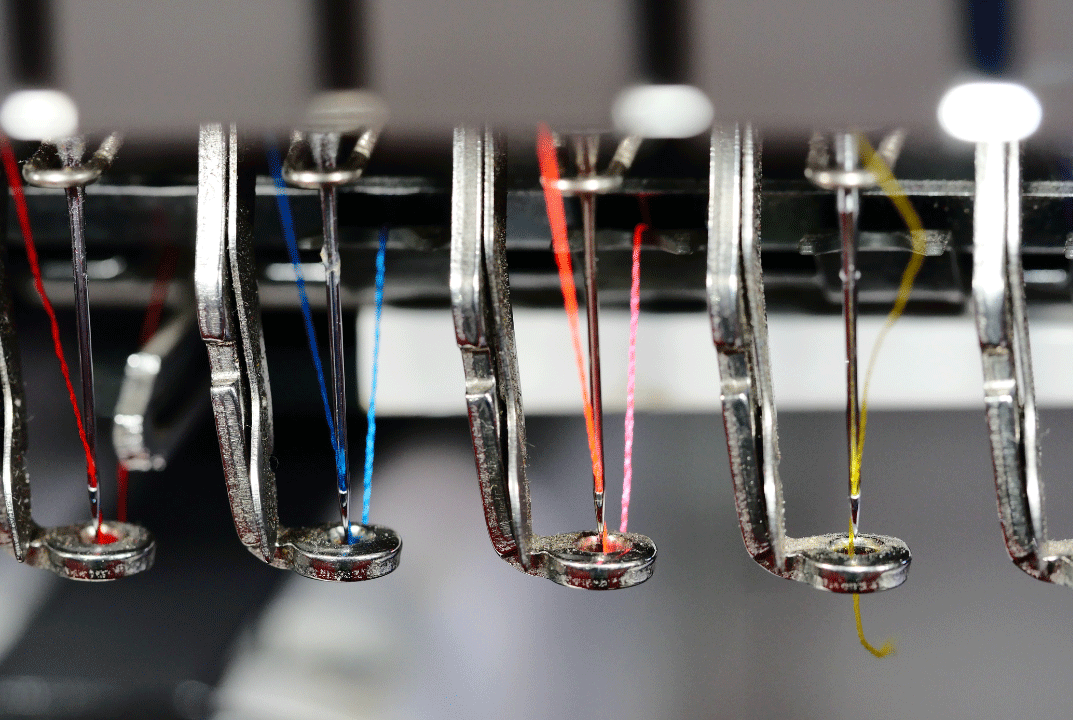

A multi-needle embroidery machine typically features 4 to 15 needles, allowing you to assign a different thread color to each one. This makes it a powerful tool for professional embroiderers.

Advantages:

- Automated Thread Changes

Multi-needle machines are equipped with multiple needles (typically 4 to 15), allowing you to assign a unique thread color to each one. This eliminates the need for manual thread changes during your design, saving time and reducing interruptions. For complex, multi-colored designs, this feature ensures smooth, uninterrupted production and consistent results. - Faster Production Speed

Multi-needle machines are designed for efficiency. They not only automate thread changes but also operate at higher stitching speeds, typically 800 to 1,200 stitches per minute. This makes them ideal for businesses handling bulk orders or tight deadlines. You can complete designs in a fraction of the time it would take with a single-needle machine. - Multiple Hooping Options

Multi-needle machines often come with a variety of hoop sizes, giving you the flexibility to work on projects both big and small without additional investments. They also support specialty hoops for hats, sleeves, and other hard-to-embroider areas, expanding your range of product offerings.

Disadvantages:

- High Initial Cost

Multi-needle machines can cost anywhere from $5,000 to $20,000 or more, depending on the number of needles, features, and brand. For small businesses or hobbyists, this significant upfront expense may be a barrier. Additionally, you’ll need to budget for ongoing costs like maintenance, replacement parts, and high-quality threads to ensure the machine performs optimally. - Noisy Operation

Multi-needle embroidery machines tend to be louder than single-needle models, especially at higher speeds. If you’re working in a shared or home environment, the noise level could be disruptive, requiring soundproofing or operating the machine during specific hours. - Increased Complexity of Thread Management

While having multiple needles is an advantage, managing them can become complicated. Thread tension, thread breakages, and color sequencing must be carefully monitored to avoid errors. Incorrect setup can result in flawed designs, wasted materials, or downtime spent rethreading and reconfiguring the machine. - Larger Space Requirements

These machines are typically much bigger and heavier than single-needle models, requiring a dedicated workspace. You’ll need to factor in enough room for the machine, various hoops, supplies, and potentially a stand. If you’re running a home-based business in a small space, accommodating a multi-needle machine can be challenging.

How to Choose the Right Machine for Your Business

- Assess Your Business Goals

If you’re starting a home-based business with small, custom orders, a single-needle machine may suffice.

For high-volume orders or if you plan to grow quickly, a multi-needle machine is a better long-term investment. - Consider Your Budget

Factor in not just the machine’s cost but also accessories, maintenance, and supplies. Single-needle machines are budget-friendly, but multi-needle machines can pay off with higher productivity. - Evaluate Your Workspace

Single-needle machines are compact and portable, while multi-needle machines require dedicated space and can be loud. - Think About Your Projects

Single-needle machines are great for smaller projects like monogramming. Multi-needle machines excel at larger or more complex designs with multiple colors.

When to Upgrade from Single-Needle to Multi-Needle.

Many embroiderers start with a single-needle machine and upgrade as their business grows. Signs it’s time to upgrade include:

- Increased order volume.

- Frustration with frequent thread changes.

- Need for faster production to meet deadlines.

- Limited hoop sizes.

- Wanting to make caps or expand to other products

What Are The Top Embroidery Machine Brands?

- Brother USA

Website: https://www.brother-usa.com

Notable Models:

Brother SE1900: A versatile sewing and embroidery machine with 138 built-in designs and a 5″ x 7″ embroidery area. Brother PE800: An embroidery-only machine featuring 138 built-in designs and a 5″ x 7″ embroidery field.

- Janome America

Website: https://www.janome.com

Notable Models:

Janome Memory Craft 500E: An embroidery-only machine with 160 built-in designs and a maximum embroidery size of 7.9″ x 11″.

- Bernina USA

Website: https://www.bernina.com

Notable Models:

Bernina 700: An embroidery-only machine offering a large embroidery area and precise stitching.

- Singer

Website: https://www.singer.com

Notable Models:

Singer Legacy SE300: A sewing and embroidery machine with 200 built-in embroidery designs and a maximum embroidery area of 10.25″ x 6″.

- Husqvarna Viking

Website: https://www.husqvarnaviking.com

Notable Models:

Husqvarna Viking Designer Topaz 50: A sewing and embroidery machine with a large embroidery area and numerous built-in designs.

- Baby Lock

Website: https://www.babylock.com

Notable Models:

Baby Lock Flourish II: An embroidery-only machine with 181 built-in designs and a 6.25″ x 10.25″ embroidery field.

- Pfaff

Website: https://www.pfaff.com

Notable Models:

Pfaff Creative 1.5: A sewing and embroidery machine with a 6″ x 10″ embroidery area and various built-in designs.

Conclusion

Choosing between a single-needle and multi-needle embroidery machine comes down to your budget, goals, and how much you plan to produce. Single-needle machines are awesome for beginners or smaller projects, while multi-needle machines are a game-changer if you’re ready to scale up your business.

Whichever machine you choose, there’s one thing every design needs: digitizing. This is what turns your artwork into a stitchable format for your embroidery machine. It’s not as simple as uploading an image and pressing start, but don’t worry—we’ve got you covered! With over 20 years of experience, we create custom embroidery files that are ready to go, so you can focus on bringing your designs to life.

Starting an embroidery business is such an exciting journey, and having the right tools and support makes all the difference. If you have questions or need help with digitizing, feel free to reach out—we’d love to help you get started!